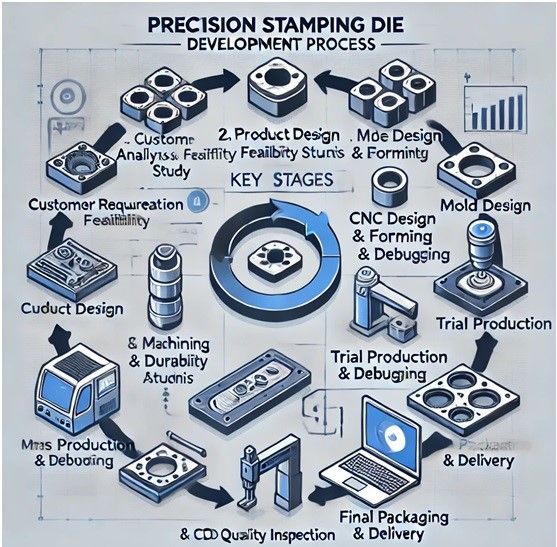

Die OEM development

Precision Stamping Die Design and Development — Engineered for Accuracy, Built for the Future.

In the field of high-speed precision manufacturing, Taiwan King Pin Terminal Co., Ltd. utilizes leading precision continuous stamping die technology to help you create the most competitive products! We offer a comprehensive process from mold design, mold manufacturing, trial production to mass production, ensuring production efficiency and quality stability, with every part achieving micron-level precision!

Professional Technology, Creating Ultimate Precision

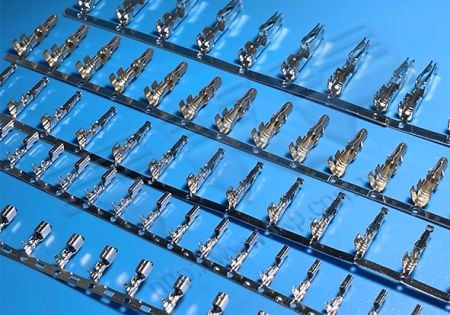

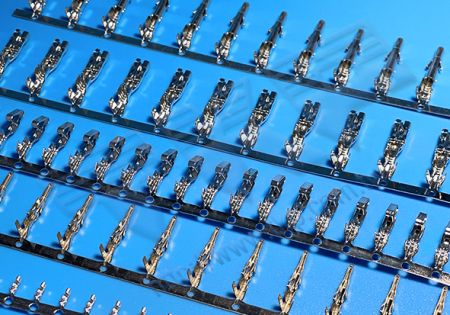

1.High-Precision Continuous Stamping:

1. Stable mass production to meet the demands of the electronics and automotive markets。

2.Advanced Stretching Analysis:

Predicts metal deformation to ensure precision in thin sheet forming, eliminating cracks and wrinkles。

3.Mold Durability Analysis:

Optimizes mold lifespan, reduces maintenance costs, and enhances production stability。

4.High-Toughness Mold Steel:

Extends mold life, ensuring long-term precision production。

5.Optical CCD Full Inspection Equipment:

100% high-precision inspection to ensure defect-free parts。

6.Composite Processing Technology:

Integrates stamping and injection molding to enhance product strength and lightweight design。

【Professional Applications】

High-end markets such as electronic 3C connectors, automotive connectors, and LED optoelectronic parts. Whether it's terminals, spring clips, or electronic components, Taiwan King Pin Terminal Co., Ltd. Company provides the most precise and reliable solutions。