Insert Molding

Precision Injection Molding by Taiwan King Pin Terminal Co., Ltd. — Leading with Insert and Over-Molding Toward a Smarter Manufacturing Future

In the rapidly evolving manufacturing industry, high-precision injection molding technology has become the key to ensuring product quality and enhancing competitiveness. Taiwan King Pin Terminal Co., Ltd. has over 30 years of professional experience, specializing in insert molding and over-molding technologies. By combining innovative design, precise mold development, and smart manufacturing, we provide customers with efficient, stable, and high-quality solutions.

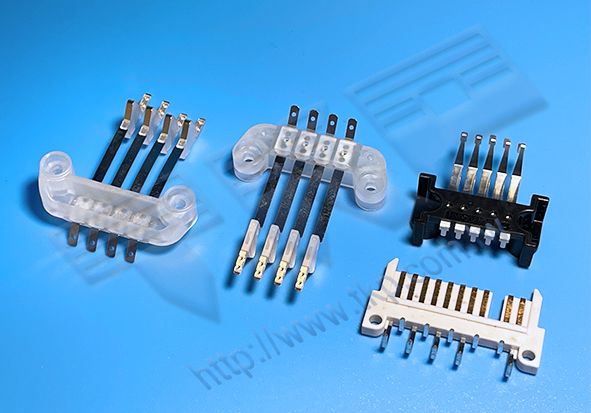

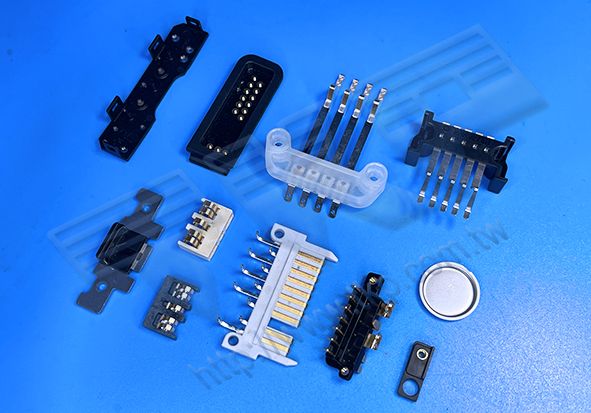

■Insert Molding — Precision Integration, One-Piece Molding

Taiwan King Pin Terminal Co., Ltd. uses high-precision injection molding technology to directly embed metal, electronic components, or other dissimilar materials into plastic molding, ensuring precise fixation of parts, enhancing mechanical strength, and improving product durability。

1.High Integration:

Reduces part assembly and increases production efficiency。

2.Strong Adhesion:

Tight bonding between plastic and metal/electronic components, improving product stability。

3.Cost Reduction:

Reduces secondary processing requirements and improves production yield。

■Over-Molding — Perfect Coverage, Ultimate Protection

For special applications, Taiwan King Pin Terminal Co., Ltd.’s over-molding technology can form a protective layer on the surface of products, effectively improving water resistance, impact resistance, and comfort, widely used in electronic connectors, automotive parts, medical devices, and 3C products。

1.Enhanced Durability:

Waterproof, dustproof, and impact-resistant, suitable for harsh environments。

2.Ergonomic Design:

Improves grip and operational comfort。

3.Efficient Process:

Multi-material one-piece molding reduces traditional assembly steps。

■Industry-Leading Smart Manufacturing — AOI 100% Automatic Inspection, No Compromise on Quality

Taiwan King Pin Terminal Co., Ltd. has developed its own in-mold AOI (Automatic Optical Inspection) technology for stamping and molding. Each product undergoes 100% inspection, ensuring defect-free and flawless parts, providing customers with peace of mind!

1.Intelligent Production:

Integrated mold design and automated injection molding operations ensure product consistency。

2.Real-time Defect Detection:

AOI inspection ensures the elimination of minor defects and guarantees 100% product compliance。

3.International Standard Quality:

Complies with ISO 9001, IATF 16949, and global certification standards。

We sincerely invite you to visit Taiwan King Pin Terminal Co., Ltd. and witness the ultimate power of high-end injection molding technology!

Taiwan King Pin Terminal Co., Ltd. is not only an expert in injection molding but also a technological leader in the connector industry! We welcome partners from all industries to visit and experience how we perfectly integrate precision injection molding with smart manufacturing, creating a future of efficiency, sustainability, and ultimate quality!