Plastic mold OEM development

Seamless Integration, Precision Molding! From design to mass production, we deliver one-stop solutions to bring your ideal plastic products to life.

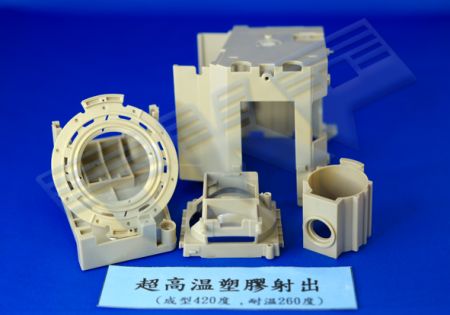

We focus on providing high-precision engineering plastic injection molding services, specializing in handling various high-temperature engineering plastics, including PEEK, PVDF, PEI, PI, and PA66, among other high-performance materials, to meet the strict material performance requirements of various industries. Our injection molding technology ensures the accuracy of every detail, enhancing the overall competitiveness of the products.

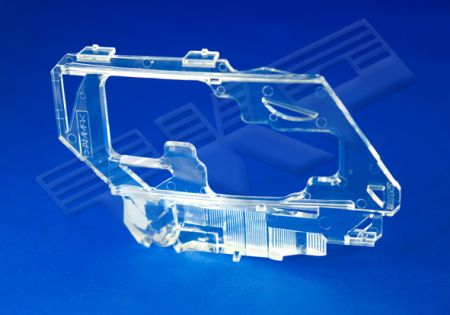

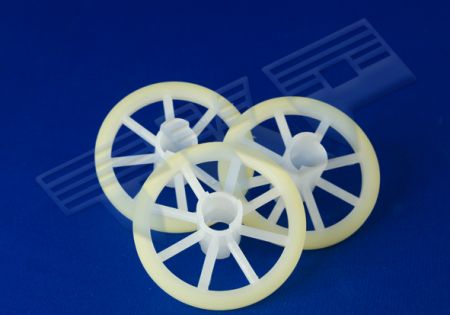

Whether it's mold development and injection needs for PCB wet equipment gears, hand tools, or automotive and motorcycle peripheral products, we offer professional and flexible solutions. From design to mass production, our team will tailor the most suitable production process according to your needs, delivering stable and high-quality products.

Our Advantages:

1. High-Temperature Material Application:

We select high-heat-resistant materials such as PEEK, PVDF, and PEI, suitable for high-temperature environments. These materials are corrosion-resistant and have high strength, ensuring long-term stable product performance。

2. Precision Manufacturing:

With precise injection molding technology, we ensure that every detail of the product meets your requirements, whether it's a complex structure or a small size。

3. Advanced Mold Flow Analysis:

Precise simulations during the mold design phase reduce trial mold costs and improve manufacturing yield。

4. Diverse Application Fields:

Our injection molding technology is widely used in industries such as PCB equipment, hand tools, and automotive parts. No matter how unique your needs are, we can provide professional solutions。

5. ODM Services:

We offer comprehensive ODM services, designing and producing customized products based on your requirements. From prototype design to mass production, we guarantee efficiency and precision at every step。